Drum filling machines are vital objects for companies that take care of and deal bulk liquid merchandise. Normally applied within the chemical, food, pharmaceutical, and industrial sectors, this devices is developed to accurately fill substantial containers like 200-litre drums or Intermediate Bulk Containers (IBCs) with liquids of assorted viscosities—from h2o-like fluids to weighty oils and pastes.

The first perform of a drum filling device would be to make certain speedy, safe, and specific filling of massive drums, minimizing spillage and solution loss. This is especially significant whilst confronting higher-value or harmful products, where even compact inaccuracies can lead to sizeable waste, safety dangers, or regulatory non-compliance.

Contemporary drum filling units include Highly developed characteristics such as electronic weigh scales, flowmeters, and automatic nozzles that detect the fill amount in actual time. These options empower the machine to close above movement routinely when the wished-for bodyweight or volume may be attained, making certain steady and correct final results. Several techniques also arrive with drip trays and splash guards to spice up cleanliness and safety.

Adaptability is known as a vital good thing about drum filling devices. No matter if handling absolutely click here free-flowing liquids, semi-viscous items, or corrosive chemicals, machines might be customised with assorted nozzles, seals, and resources (like stainless-steel or PTFE) to match certain solution prerequisites. Filling could be accomplished in the prime or bottom Together with the drum, and devices may be A part of current conveyor or pallet techniques for seamless Procedure.

An occasion of a company Within this House is Flex Pack Service & Materials in Australia. They offer a number of semi-automated and guide drum filling devices that cater to various industrial desires. Their items are pointed out for its robustness, very simple operation, and compatibility with Clear-In-Position (CIP) methods, which makes them ideal for businesses focused on hygiene and performance.

Investing inside of a superior-excellent drum filling equipment not basically enhances productiveness but Also cuts down within the chance of operator error and workplace incidents. By automating the filling course of action, companies can obtain improved consistency, reduce labor costs, and adhere to rigorous high-quality and security expectations.

In summary, drum filling machines undoubtedly are a wise Resolution for nearly any organization that should package massive volumes of liquid speedily, properly, and securely. They supply a robust, scalable strategy to cope with demanding industrial packaging responsibilities and solution integrity.

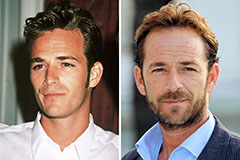

Luke Perry Then & Now!

Luke Perry Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Christina Ricci Then & Now!

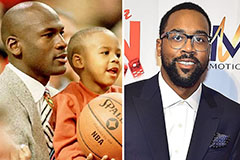

Christina Ricci Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!